What Is cold pressed extra virgin olive oil?

A Deep Dive Into Process, Meaning, and Why It Matters

Cold Pressed, and Extra Virgin: Where the Terms Comes From, and Why They Still Matter

“Cold pressed” is kind of a historical term. Traditionally, olives were crushed into a paste using stone wheels, then that paste was layered between jute mats, then pressed using a wooden screw. No added heat, just pressure. By the standards of that time, the oil that came out of that was the highest quality, the most aromatic, and the freshest.

“'Cold pressed' is about the process. 'Extra virgin' is about the result. But the two are absolutely connected."

The paste would occasionally be reconstituted with hot water and subject to further pressing to pull out more oil, thus the term “first cold pressed” to denote the highest quality oils, with other oils being considerably lower quality, as the paste is a very delicate product, with the oils being exposed to air (promoting oxidation) and the being in contact with the pulverized fruit, which is subject to both biological and enzymatic degradation.

So “cold pressed” became this shorthand for the good stuff. No heat, no second pressings. Just the oil that comes out when you do it right the first time. If you'd like some of The Good Stuff, you can check out our Cold Pressed Olive Oils here.

Table of Content

What Cold Pressed Actually Means (and Doesn’t Mean) Today

Here’s where things get a little murky. Today, cold pressing doesn’t usually mean someone’s out there with stone wheels and jute mats. It’s about the conditions under which the oil is extracted, specifically, that the temperature stays below 27°C, or about 80°F, during processing. That’s the EU standard.

But there are ways to meet the technical definition of “cold pressed” while still cutting corners. You can heat the paste to this limit and hold it there for hours to maximize extraction, and while it would still be considered cold pressed or extra virgin, the oil will still be heavily oxidized.

In our case, cold pressed really means: minimal time, minimal oxygen, no heat, one pass. We take the olives straight from harvest, run them through a mill that we’ve dialed in to avoid degrading the oil, and we move fast. The goal is always the same, protect the aromatics and get it into a container under nitrogen as fast as possible to ensure we produce the best, polyphenol rich olive oil every year.

Time and Heat Are the Enemies of Flavor and Nutrition

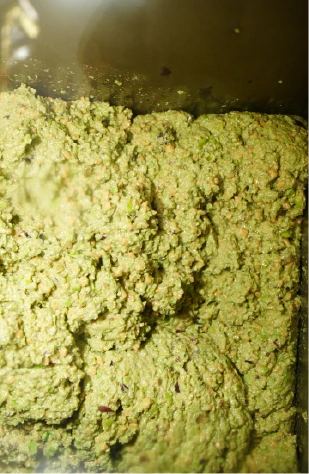

What most people don’t realize is how fragile olive oil is during extraction. Once you crush the olives and make a paste, you’ve essentially got a perishable mixture. There’s moisture, there’s air, there’s heat being generated from friction, all of which can start breaking things down almost immediately, and degrade the health benefits of cold pressed olive oil.

Even the act of stirring the paste, which is called malaxation, introduces oxygen. If you do that for too long, or at too high a temperature, you lose aromatics. You lose that bright, green, peppery thing. You lose the polyphenols.

We process everything in a single pass, no reheating, no second runs, and we control the temperature every step of the way. The oil goes through a stainless steel crusher, into a sealed malaxer where it’s gently stirred under nitrogen, and then immediately centrifuged and filtered. We sparge with nitrogen, too, and backfill our tanks before we draw from them. The whole system is set up to minimize oxidation and lock in freshness.

There’s a reason our organic extra virgin olive oils hit 400-600 ppm polyphenols on a regular basis. It’s not just the fruit, it’s the process.

Olive Paste Being Gently "Malaxed" In Our Olive Mill To Prepare It For Separation.

Check Out Some Of Our Cold Pressed Olive Oils

How "Cold Pressed" and "Extra Virgin" Relate To Each Other

To qualify as extra virgin, an oil has to meet strict chemical and sensory standards. It can’t be oxidized. It can’t have defects like rancidity or fustiness. A certified taste panel has to agree that it’s clean, fresh, and balanced. There’s also lab testing for things like free acidity, peroxide values, UV absorbance, all indicators of how the oil has been handled.

So the way I look at it is: cold pressing is the best path to making extra virgin olive oil, but it’s not a guarantee. You could use a cold press method, but if your fruit was compromised, damaged, moldy, overripe, or if you let the paste sit too long, you might still end up with a defective oil.

And the reverse is also technically true: you could use a more modern “cold extraction” process, which doesn’t involve a literal press at all, and still get extra virgin. That’s what we’re doing, cold extracting in a way that honors the spirit of cold pressing. We’re not using stone wheels, but we’re absolutely preserving the things that matter: freshness, flavor, health benefits.

Owner, Patrick Martin, Inspecting our new filtration system, designed in house to preserve polyphenols, aromatic compounds, and health benefits of our cold pressed olive oils.

What to Look For (and Watch Out For) on Olive Oil Labels

The tricky thing is that these terms, “cold pressed,” “extra virgin”, are used all over the place, and not always honestly. A lot of supermarket oils will say “cold pressed” on the label, but the fruit was stored in bins for days or processed at scale with little attention to quality. Legally, they might be in the clear. But practically, the oil is a far cry from what a small producer like us is doing.

Look for transparency. Look for harvest dates. Look for producers who tell you about how they process, not just what certification they have. Because certifications tell you that a sample passed a test, they don’t tell you the full story of how the oil was made.

We bottle to order. We store under nitrogen. We filter immediately. That’s the level of care that makes a difference, and that’s what people can taste when they try our oil. And if you're looking for a real treat, you can check out our Olio Nuovo, the first olive oil release of the season for those looking for the freshest and most incredible olive oil available.

Cold Pressed Isn’t a Buzzword Here, It’s a Commitment

For us, “cold pressed” isn’t a marketing term, it’s a guiding principle. It’s about respect for the fruit, for the land, and for the people who use our oil in their kitchens.

We don’t try to stretch our yield. We don’t reprocess. We don’t let paste sit around. We’re trying to make something alive and expressive, something that tastes like the place it came from and the moment it was harvested.

It’s not the easiest way to do it. It’s not the cheapest. But it’s the way to make oil that’s worth paying attention to. And that’s why cold pressed still matters, because when it’s done right, it’s not just a process. It’s a promise.

TL;DR

→ “Cold pressed” means no heat during extraction, preserving flavor and polyphenols.

→ Modern milling systems can still be “cold pressed” if temperatures are kept low and oxidation is minimized.

→ “Extra virgin” is a grade based on chemical and sensory tests; cold pressing is the most reliable path to achieving it.

→ Not all “cold pressed” claims are equal, watch for transparency and detail.

→ At Frantoio Grove, cold pressing is integrated into every part of the process, from harvest to bottle.